The DTF Powder Applicator is a specialized tool for precise application of powder coating on fabrics, ideal in the garment industry. With its roller and controlled chamber, it ensures even distribution and consistent coating, suitable for various materials from cotton to synthetic fabrics. Facilitating intricate UV DTF transfers and vibrant heat transfers, its design allows easy navigation around curves. Regular cleaning with mild soap and warm water, proper storage in a cool dry place, and careful handling are crucial for maintaining performance and longevity of the applicator.

Maintaining your DTF Powder Applicator is key to ensuring its longevity and optimal performance. This versatile tool, designed for precise application, comprises several parts that work harmoniously. By understanding each component and its function, you can implement effective cleaning and storage practices. Regular maintenance prevents clogs and ensures consistent results. Follow these simple tips to extend the life of your DTF Powder Applicator and keep it ready for your next creative project.

- Understanding the DTF Powder Applicator: Its Parts and Functionality

- Regular Cleaning and Maintenance Tips for Optimal Performance

- Storage and Handling Practices to Ensure Longevity

Understanding the DTF Powder Applicator: Its Parts and Functionality

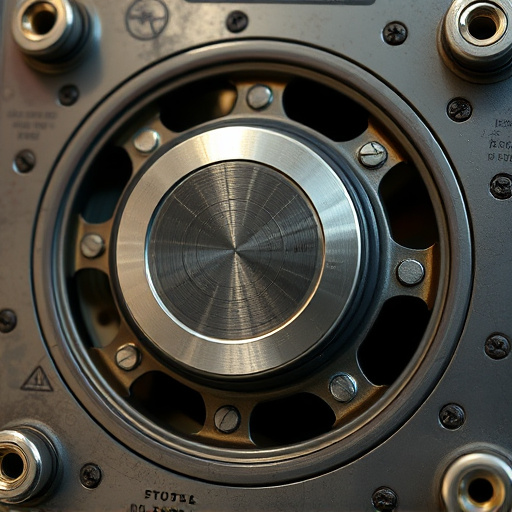

The DTF Powder Applicator is a specialized tool designed for precise and efficient application of powder coating, especially in the garment industry. Comprising several key parts, its functionality revolves around a simple yet effective process. The applicator’s main component is the roller, which evenly distributes the powdery substance onto fabric surfaces. This roller is housed within a chamber that controls the amount of powder released, ensuring a consistent and controlled coating.

The device’s versatility allows it to be used with various materials, from cotton dtf printed shirts and synthetic fabrics to creating intricate UV dtf transfers and vibrant heat transfers. Its design facilitates easy navigation around curves and edges, making it suitable for detailed work. Regular cleaning and maintenance are crucial to prolonging the DTF Powder Applicator’s lifespan, ensuring it remains a reliable tool for achieving high-quality finishes in textile printing and decoration.

Regular Cleaning and Maintenance Tips for Optimal Performance

Regular cleaning and maintenance are essential for preserving the performance and longevity of your DTF Powder Applicator. After each use, take a few minutes to carefully wipe down the applicator’s surface with a soft, damp cloth to remove any excess powder and prevent clumping. This simple step goes a long way in maintaining the device’s accuracy and ensuring consistent results for your DTF heat transfers.

For deeper cleaning, especially if you’ve been using vibrant or moist powders, consider disassembling the applicator according to the manufacturer’s instructions. Use mild soap and warm water to clean all components, paying special attention to nooks and crannies where powder might accumulate. Rinse thoroughly and allow all parts to air dry completely before reassembling. Maintaining a high-quality DTF print quality requires regular upkeep, so make this a habit to extend the life of your applicator and enjoy precise, long-lasting DTF transfers.

Storage and Handling Practices to Ensure Longevity

Proper storage and handling are key to extending the lifespan of your DTF Powder Applicator. After each use, ensure that the applicator is thoroughly cleaned with a soft brush or cloth to remove any residual powder. Store it in a cool, dry place away from direct sunlight and heat sources. Consider using an airtight container to protect it from moisture and dust accumulation.

When handling your DTF Powder Applicator, be gentle and avoid forcing it onto surfaces. The delicate design is meant for precise control during application. Remember that proper storage and careful handling will significantly contribute to the longevity of your applicator, ensuring optimal performance whenever you need to use it for various DTF application instructions or even for creating captivating dtf logo transfers and gang sheet builder designs.

Maintaining your DTF Powder Applicator is key to ensuring its longevity and optimal performance. By regularly cleaning, properly storing, and handling with care, you can extend the life of this essential tool. Remember to disassemble, clean each part thoroughly, and store in a cool, dry place. With proper maintenance, your DTF Powder Applicator will continue to deliver precise and consistent results for years to come.