Choosing a DTF Powder Applicator depends on intended use, budget, and substrate type for optimal print results. Evaluate precision, control, ease of use, and maintenance for efficient production. For business needs, consider capacity, pattern handling, color accuracy, material quality, fabric compatibility, and user-friendly features.

Choosing the right DTF (Direct To Fabric) Powder Applicator is a game-changer for businesses looking to enhance their printing processes. This article guides you through understanding DTF applicators, their diverse uses, and key factors in making an informed decision. We’ll delve into top considerations specific to business applications, ensuring you select the ideal tool to revolutionize your fabric printing, elevate productivity, and meet client demands efficiently.

- Understanding DTF Powder Applicators and Their Uses

- Key Factors in Selecting the Ideal Applicator

- Top Considerations for Business Applications

Understanding DTF Powder Applicators and Their Uses

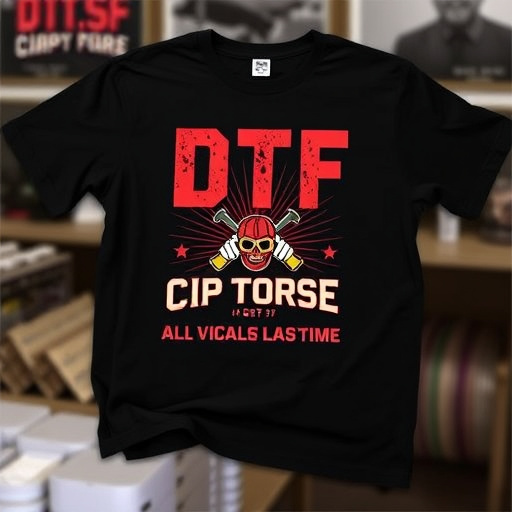

A DTF Powder Applicator is a specialized tool designed to evenly distribute and apply dry transfer powder (DTF) onto various surfaces, primarily used for creating prints on t-shirts and other textiles. This process, also known as heat transfer printing, involves a unique method where the powder acts as a carrier for designs, which are then fused onto the fabric using heat and pressure. DTF applicators come in different forms, from manual tools to automated machines, each tailored to specific applications and production scales.

Understanding how these applicators work is crucial when setting up a business focused on dtf prints. For instance, manual applicators are suitable for smaller-scale projects or hobbyists, allowing precise control over the application process. On the other hand, automated systems offer speed and efficiency for high-volume production, making them ideal for businesses aiming to meet market demands swiftly. Choosing the right applicator depends on factors like intended use, budget, and the type of dtf heat transfer paper used, ensuring optimal results in every print job.

Key Factors in Selecting the Ideal Applicator

When choosing a DTF Powder Applicator for your business, several key factors come into play. Firstly, consider the type of products you intend to print on—whether it’s custom t-shirts, hoodies, or other garments. Different applicators are designed for specific substrates, ensuring optimal printing results and quality. For instance, a direct-to-film (DTF) printer is ideal for creating intricate designs on various materials without the need for cutting or weeding.

Secondly, the level of precision and control offered by the applicator should align with your business’s requirements. Some models feature advanced nozzles and adjustable settings, enabling precise application of powder, especially in detailed areas. This is particularly beneficial for high-quality, personalized DTF printing on hoodies and other garments that demand intricate designs. Additionally, ease of use and maintenance are essential considerations to ensure efficient production and minimize downtime.

Top Considerations for Business Applications

When selecting a DTF Powder Applicator for business applications, several key considerations come into play to ensure optimal results. First and foremost, understand your specific needs in terms of DTF for t-shirts or DTF for apparel printing. Different applicators are designed with varying capacities and precision levels, catering to small-scale or large-volume production. For clothing brands aiming to create unique designs with logos DFT for clothing, consider the applicator’s capability to handle intricate patterns and its adherence to color accuracy standards.

Material quality is another vital factor. Look for applicators made from durable materials that can withstand frequent use, especially if you plan to incorporate this technology into your core business operations. Compatibility with various fabric types is essential, as is the ability to achieve consistent results across different DTF for apparel applications. Additionally, consider user-friendly features like easy cleaning mechanisms and adjustable settings to streamline your printing process.

Selecting the appropriate DTF Powder Applicator can significantly impact your business’s efficiency and product quality. By understanding the diverse applicators available and considering factors like material compatibility, powder flow, and ease of cleaning, you can make an informed choice to meet your specific needs. For businesses seeking a reliable partner in the realm of DTF Powder Applicators, prioritizing top-tier construction, precise engineering, and customizable options will ensure optimal performance and longevity.